Published: 10/30/20, Last updated: 5/21/25

Introduction

For meat eaters, bacon is a delicious staple that finds a home on breakfast, lunch and dinner plates. Yet that crispy, salty goodness hides some ugly truths about the pork industry. Those truths were starkly revealed in April 2020 when pork processing plants temporarily shut down to slow the spread of COVID-19. One of the largest to close, a Sioux Falls, South Dakota Smithfield plant, waited more than three weeks to do so, by which time there were at least 644 positive cases and one death reported, and the town of Sioux Falls had become the single largest virus hot spot in the nation.1

The closure of the Sioux Falls plant and others had ripple effects on farms and supermarkets across the country: with nowhere to send their mature hogs for processing and no more space in their barns, hog farmers saw their prices collapse and chose to euthanize their animals instead, horrifying people with the cruelty and waste. As sausage and pork prices spiked at grocery stores and lines grew at food banks, Smithfield warned of potential long-term shortages.2

When President Donald J. Trump signed an executive order to reopen the plants — much too quickly, according to public health experts, and with no mandated worker protections3 — things got even worse: by late June, just two months after the order, over 27,000 meatpacking plant workers had tested positive for COVID-19 and nearly 100 had died,4 while infection rates in surrounding rural communities were five times higher than the rest of rural America.5 Meanwhile, there wasn’t a problem with US pork supply at all: in April, the pork industry exported a record amount of pork to China.6

The impacts of plant closures were felt so acutely because the pork industry is highly concentrated — and the dangerous, export-focused re-openings happened so quickly because the companies at the top wield so much political power. Just over 30 pork plants process 92 percent of all US pork,7 with the Sioux Falls plant alone accounting for 5 percent. On the farm side, 40 hog producers control two-thirds of all breeding hogs.8 Such intense consolidation makes a system fragile: with capacity concentrated in so few locations, a disease outbreak or shutdown at one high-volume farm or plant can have effects around the country.

Thirty years ago, hogs were raised on the kind of idyllic farms pictured on the sausage packaging. They were a reliable income stream for independent farmers and rural communities and a useful part of a diversified farm. Meatpacking was a union job and a reliable path to the middle class. Today, meatpacking jobs are low-paid and dangerous; hogs are raised by the thousands in enormous climate-controlled barns next to lakes of their own manure — and the stench and pollution can make life unlivable for nearby residents.

These changes were made in the name of progress, but the main beneficiaries have been the top pork companies. After decades of cutthroat takeovers and mergers, just a few big firms control the industry. Smithfield, the largest, has been owned by a Chinese company since 2013. Tyson Foods, the second-largest in pork, is also the top producer of chicken and beef. The third-largest in pork and the second-largest in beef is the Brazilian-owned company, JBS USA. These three companies have built the meat industry into a global force, accounting for nearly $1 trillion in annual output,9 greater than the entire GDP of many countries. Sacrificing workers and rural communities to keep up production for export to China is nothing new. For decades, they have expanded the economic and cultural power of the pork industry in the US and around the world by molding policies and politicians to their will, writing state laws to boost their business, and attacking both environmental regulations and community advocates that threatened to cut into their profits.

Before the pandemic shone a light on meatpacking plants, most Americans were not seeing these changes on their plates. But around the country, the massive consolidation of the pork industry has had devastating effects on the ground in regions where hog operations and meatpacking plants proliferate: where people do not leave their homes because of the stench, where rivers and well water are poisoned by manure runoff, where hog farmers are trapped in debt, where meatpacking workers face serious injury just by showing up, and where animals (with intelligence similar to primates) spend their lives in cages too small to turn around in.

While pork may well be the worst of the livestock industries, the good news is that other models are possible. People are trying new models for raising hogs, drawing from what worked in the past. They are forming partnerships to navigate today’s complex pork economy, through farmer cooperatives and small-scale middlemen. Communities are fighting back, organizing neighbors, and battling Big Pork in the legislature and in the courts. All of this is good for farmers, good for workers, good for the community, and good for the environment.

A Decade That Changed The Pork Industry

Until the mid-1990s, hogs were widely raised across the country by independent farmers. Cheap to feed on scraps, cheap to house in hutches or barns, they reached market weight in under a year. So many families were relying on the extra income from raising a few hogs and selling them at local livestock auctions that the animals came to be known as “mortgage-lifters;” hog buyers would bid against each other, and with that competition, farmers generally got a fair price.

In the early 1990s, 87 percent of hogs were sold on the open market, and the top four pork packing companies controlled 46 percent of the market.10 Huge change swept the industry in the late 1990s. By 2001, only 17 percent of hogs were sold on the open market,11 leaving even fewer options for small-scale hog farmers to sell their animals. It has only gotten worse: in 2018, only two percent of hogs were sold on the open market. For the other 98%, farmers are on contract with big pork companies and get paid for raising animals according to the company’s strict guidelines.12

Vertical Integration and Consolidation

The pork industry around this time was squeezed by the skyrocketing popularity of chicken, which had exploded, once pioneers like Tyson Foods bought up all parts of the supply chain, from feed companies to slaughterhouses, in a process called vertical integration. Chicken was suddenly cheap to produce and cheap to buy at stores, where it cut into sales of pork.13 To catch up, the pork industry (led by the Smithfield), imitated Big Chicken’s business model, vertically integrating its supply chain, putting hogs indoors in massive barns, and contracting with farmers to raise them.14

The contract arrangement worked well for some farmers, but as big meatpackers controlled more and more of the market, local livestock auction houses disappeared. In many regions today, there are only one or two pork packers and no auction houses, so hog producers have few potential buyers. The loss of competition has made farmers’ prices plummet: in the early 1990s, hog prices averaged $81 per hundred pounds (in 2014 dollars); in the early 2010s, average prices had dropped nearly 20 percent, to $68 per hundred pounds.15 Today farmers receive only 19 percent of the retail value of a hog.16

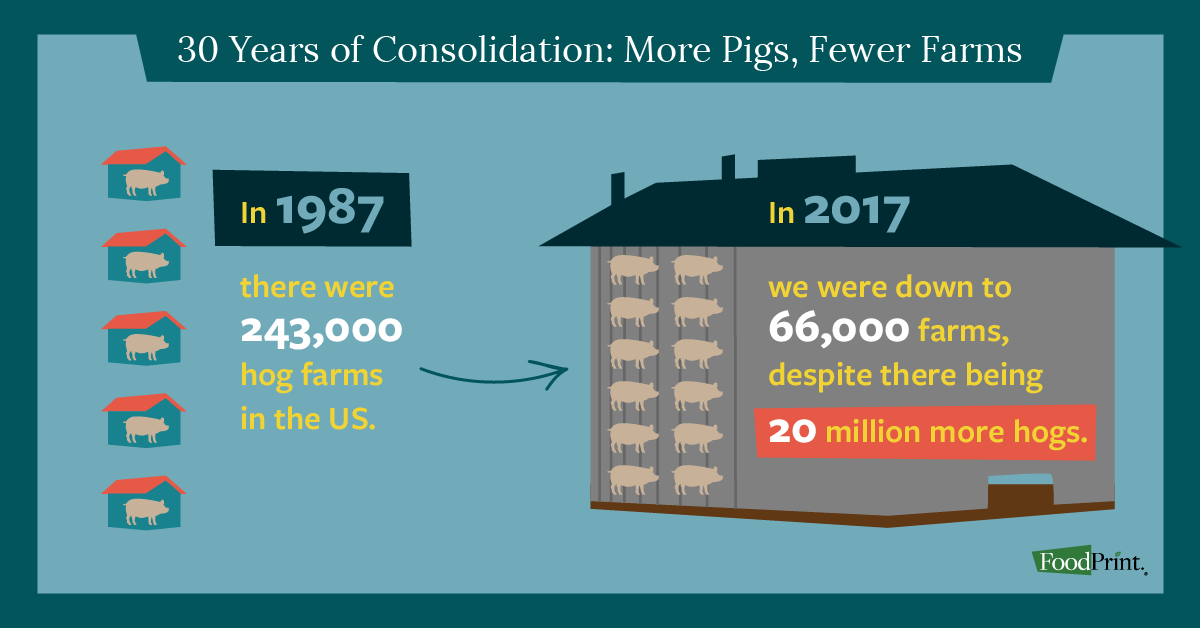

So, it is no wonder that independent hog farmers have gone out of business by the hundreds of thousands. Since 1987, the number of hog farms has dropped nearly 75 percent, from 243,000 to 66,000 in 2017.17 Meanwhile, the number of hogs has steadily increased, from 52 million in 1987 to 72 million in 2017.18 Today, 61 percent of hog slaughter is controlled by just three companies: Smithfield, Tyson Foods and JBS USA.19

In the pork industry, as in many others, these firms got to the top not by being the most efficient, but by simply buying out their competition. For instance, Smithfield, founded in 1936 in Virginia, bought Circle Four Farms in 1997; Carroll’s Foods, the country’s fourth-largest hog producer, in 1999; Murphy-Brown, the largest, in 2000; and Farmland Foods, the sixth largest, in 2003, before Smithfield itself was purchased in 2013 by Chinese-based Shuanghui International, now called WH Group. At the time of the buyout, Smithfield owned not only all of the producers it had been buying up, but also North Carolina’s two largest pork processing plants.20 With each new asset, Smithfield controlled a larger share of the market, making it even easier to make the next purchase. Tyson and JBS have grown in the same manner, until much of the global meat industry is controlled by these three corporations.21

Contract Farmers and Immigrant Meatpackers

The industry has automated as it has grown, but it still relies on workers on farms and packing plants. Contract farming is sold to farmers as a lucrative investment with guaranteed income. It is a way for vertically integrated meatpacking companies to offload the riskiest part of hog production by shifting responsibility to individual farmers.22 The farmer takes out large loans to build expensive facilities, but the company owns the hogs throughout the growing process and, in many cases, specifies everything about how they should be raised, from the style of barn and waste management system to feed and medications.23

The farmer is responsible for the manure and other waste, as well as for decommissioning the operation and its manure pits if the farmer gets out of the business. Stuck with debt and often seeing little return on their investment from the meatpackers, many contract farmers cannot afford to make the upgrades to reduce odors or avoid manure leaks that would make their operations better neighbors.24 Many even compare themselves to indentured servants, working every day of the year for little pay and no control over their operation. One Illinois farmer told a Chicago Tribune reporter in 2016, “The top dollar comes to the guy that owns the pigs, not us that raise the pigs. We are at the mercy of them. You have to go along with whatever they say. … If I weren’t in so deep, I’d never do it again.”25

As hog growers are at the mercy of the companies they contract with, the workers who slaughter and process hogs into pork are squeezed even more. For decades, meatpacking was a well-paid, unionized job, but as the industry consolidated starting in the 1980s, they fired organized workers and rehired nonunion labor instead, driving down wages and benefits.26 Meatpacking wages fell below the national average for manufacturing work for the first time in 1983; today, they are 44 percent lower, averaging $15 an hour.27 The industry uses questionable and sometimes illegal tactics to recruit workers, including targeting refugees and undocumented immigrants.28 As many as one-quarter of all meatpacking plant workers are undocumented;29 the risk of deportation or other consequences can keep them from speaking up about abuses.30

Rural Communities Struggle

As lack of markets force hog farmers out of business, rural towns suffer. The independent farmer bought supplies at the feed store, hired the local veterinarian, shopped at Main Street businesses and had an account at the local bank. Vertically integrated companies have their own feed mill and vets, and their profits go to their corporate headquarters. Low-paid contract farmers instead have less money to spend at local businesses.

While most rural farm communities are seeing population declines from these trends, a few have a different challenge. When a large pork packing plant relocates to a small town, it typically promises jobs and demands tax breaks in return. However, local residents are generally unwilling to take the new jobs, which are low paid and grueling. Despite its promises, the company instead hires people from out of town, generally immigrants or migrant workers. The town must then support an influx of new residents with no attendant increase in tax revenue to pay for the schools, hospitals and other services they need. This only adds to potential racial tensions between the mostly white residents of the town and immigrants.31

Finally, as independent hog producers and slaughterhouses have disappeared, massive industrial-scale hog barns and meatpacking facilities have moved into these rural areas, with a tremendous impact on the environment and public health, which will be detailed further below. Living near a hog operation leaves neighbors more at risk of anemia, kidney disease, higher infant mortality and lower life expectancy,32 as well as extreme stress and overall decreased quality of life.33 In states where hog waste is disposed of by spraying rather than spreading onto farm fields, the spray drifts onto and into neighbors’ yards and homes, forcing them indoors, causing asthma, headaches and nausea, and causing property values to plummet.34 Dust particles containing E. coli, Clostridium and fecal coliform bacteria have been documented on neighboring houses and even inside their refrigerators.35 Contamination of well water by these bacteria and toxic chemicals is also common.

While farmers, workers and communities struggle, the industry, becoming ever more profitable, is using its money to flex its political muscle. But before we examine how pork companies have influenced federal and state laws, let’s take a walk around a hog barn.

Industrial Hog Production: An Overview

Hogs are raised in giant barns, called Concentrated Animal Feeding Operations (CAFOs), with 800-1200 animals housed in each.36 The barns are crowded; pigs are grouped in pens of about 30 animals, giving each less than eight square feet.37 Hogs are often grouped by size, without regard to social group or family, which are naturally important to them. Slatted floors in the barns allow manure to drop into a collection pit below the barn. Giant fans provide ventilation, blowing toxic gases and dust out of the barns and into the surrounding community.

- CAFO

- Stands for concentrated animal feeding operation — a large barn with feed, lighting and temperature designed to make animals gain weight as quickly as possible.

The production cycle for swine raised in confinement begins with the breeding of the sow (female pig), either naturally or by artificial insemination. Pregnancy is about four months and piglets stay with their mother for two to four weeks. They are moved to a “growing” facility until they reach 120 pounds at three months, and to another facility at six months for “finishing,” to bring them up to their slaughter weight of 240-270 pounds.38

Animal Welfare Concerns

Pigs are intelligent and social animals, with strong and lasting family bonds.39 Tests have shown them to have cognitive and problem-solving abilities similar to primates — even working together to free themselves from pens. In natural conditions, they build and sleep in communal nests and spend up to 75 percent of their day rooting and foraging. They wallow in water or mud to stay cool, but they are clean, rubbing off dried mud and keeping waste away from their sleeping and feeding areas. The pig’s snout is exceptionally sensitive: while strong enough to cause serious damage by digging, it has numerous receptors; and the animals have an acute sense of smell.40

Like humans, pigs’ intelligence is impacted by the environment in which they are raised. There is evidence of cognitive impairment when they are kept in a barren industrial setting with no opportunity for play or other interaction with the environment.41 Packed into a dirty, smelly barn with hundreds of other unfamiliar animals and no ability to express their natural behaviors, pigs can become stressed and aggressive. Pigs raised to grow quickly for mass-market consumption have also been breed for leanness, which has had the side effect of making them jumpy and harder to manage.42

Tail Docking

In such conditions, piglets are at increased risk of biting each other’s tails, sometimes out of boredom, which can lead to infection. As a precaution, tail docking — the removal of most of the tail when the piglet is under one week old — is common practice. It is a painful procedure usually performed without anesthesia. Numerous studies have shown tail-docked pigs in typical confinement barns have fewer injuries and infections in the rest of their lives, but studies also show that providing the animals with straw or other stimulus or housing them outdoors, reduces tail biting overall, arguing against the need for tail docking in the first place.43

Health Problems from Confinement

The slatted concrete floors of barns, which let manure fall into a pit underneath, can lead to foot and leg injuries. Ammonia, hydrogen sulfide, odors, dust and other gases rise from the waste pits, causing lethargy, susceptibility to serious infection and disease, as well as respiratory problems, which are the chief cause of death for pigs in confinement.44

Gestation Crates

Perhaps worst of all, pregnant sows are kept in gestation crates — cages so small that they are unable to turn around inside. Sows can be aggressive and territorial towards other sows, especially when pregnant. The crates allow many pregnant sows to be packed into a barn without turning on each other. Following a four-month pregnancy, the sow is moved to a slightly larger farrowing crate for four weeks to nurse her piglets, and then inseminated again and returned to the gestation crate. Sow production drops off at three or four years, after which they are slaughtered.

The crates cause tremendous health problems, including sores, abscesses, lameness, respiratory and heart problems and injuries from the metal crating. One study found that one-third of crated sows had to be removed from production early because of related ailments.45 On top of physical illness, such confinement produces stress, frustration and even clinical depression in the animals, as evidenced by lethargy, unresponsiveness and repetitive and aggressive behaviors (like biting the bars of their cages until their mouths bleed).4647

A wave of consumer outcry about gestation crates in the early 2010s led to promises by more than 60 food companies — including meatpackers, restaurant chains, food service providers and supermarkets — to eliminate them from their supply chains,48 but progress has been slow and hard to track.49 Interestingly, a similar movement for “cage-free eggs” from hens raised in large barns rather than tiny cages, has been successful, at least in terms of marketing, with pledges from McDonald’s and hundreds of other companies to go cage-free by 2025.50 (Note that cage-free systems can lead to other health and welfare problems for the birds.51)

Feed

True to their reputation, pigs will eat just about anything, including grasses, roots, nuts, worms and insects, consuming both carbohydrates and protein for energy.52 In confinement, hogs are fed a feed mix of corn and soybean meal processed from genetically modified commodity grains (with attendant environmental problems of large-scale crop farming). When feed costs rise, growers may supplement the hogs’ diet with by-products from other food industries, ranging from distiller’s grain to old candy.53

Hormones and Antibiotics

Federal regulations prohibit giving growth hormones to hogs (a label touting “no growth hormones” on pork is meaningless), but other growth promoters are regularly added to feed. Ractopamine, approved by the US Food and Drug Administration (FDA) in 1999, is the most common growth promoter in the US, yielding about 10 percent more meat per hog. The drug mimics stress hormones, which stimulates aggressive behavior and increases risk of injury54 and increases heart, muscle, reproductive and endocrine problems.55 While studies of the impact of the drug on human health are limited, it is banned in China and the European Union. Meatpacking giants JBS and Tyson have phased out ractopamine in their supply chains to increase sales to China.5657 This change could essentially end use of the substance in the US pork supply, as Smithfield already does not use it.

Low doses of antibiotics are also added to feed to prevent disease in the crowded conditions of the barn and to make the animals grow faster. The low doses kill some bacteria, but those that are resistant to the antibiotic survive, creating strains of resistant bacteria that seriously threaten public health.

The FDA has issued new rules in recent years to address antibiotic resistance. Use of antibiotics explicitly for growth promotion is banned; and in 2017, the agency ruled that most classes of antibiotics deemed medically important for humans require a veterinary prescription rather than being sold over the counter. Sales of these drugs dropped by one-third in the following year.58 Another rule issued in late 2019 extended the requirement to the remaining antibiotic classes. However, the rules are voluntary, relying on drug manufacturers to change their product labels, while oversight, data collection and enforcement are weak. Producers are still getting around the rule by using the drugs for reasons of “disease prevention.” No matter the stated purpose, broadly using low levels of medically-important drugs on an entire herd for a long period of time creates the perfect conditions for antibiotic-resistant strains to arise.

Worker Welfare

Barns that are noisy and smelly are bad for hogs but even worse for workers. Repetitive stress injuries, traumatic injuries from machinery, and hearing loss from high noise levels are all common. CAFO workers are also at high risk for respiratory problems from dust and noxious gases in barns.59 Workers can become infected by viral and bacterial diseases that can jump from swine to humans. MRSA (a now-common antibiotic-resistant staph bacteria) has been found in workers’ noses, even after as much as two weeks away from the operation,60 and is transmissible to their families, as well.61

Terrible conditions are not limited to hog barns; they extend to meatpacking plants where workers do the slaughter and processing, too. The coronavirus pandemic made front-page news regarding worker safety at pork packing plants, as the close working conditions and slow industry response led to rapid spread of the virus at plants across the country. This reality isn’t new: a 2019 report by Human Rights Watch called out the industry for human rights abuses.62

770

The number of amputations, hospitalizations or loss of an eye from meat and poultry plants in nearly 30 states from January 2015 to August 2018

Meatpacking is dangerous work, with employees standing shoulder to shoulder on a “dis-assembly” line, slaughtering and cutting up more than 1,000 hogs per day at some plants. The plants are humid, slippery, loud, hot or freezing, and they smell of dead animals and chemicals. Amputations, burns, repetitive stress injuries, respiratory problems, skin infections and falls are commonplace. Worker turnover rates at hog plants averages 50 percent, going as high as 65 percent annually at some plants.63

Meatpacking employees suffer twice as many job-related injuries and illnesses as workers in other industries.64 A survey of government injury data from across many industries from January 2015 to August 2018 showed 770 reports of amputations, hospitalizations or loss of an eye from meat and poultry plants in nearly 30 states.65 When workers get hurt on site, in-house health care (which is inadequate)66 is provided, and they are discouraged from visiting outside doctors so as to keep the company’s reporting rate down.67

The speed of the processing line causes or worsens injuries. On the line, workers make the same cutting, pulling, or lifting motions thousands of times in a day, leading to cumulative trauma injuries. Sharp knives and fast-moving heavy machinery increase risks. Line speeds have gotten faster in the last 30 years,68 and the Trump administration has recently pushed further efforts to remove speed caps,69 as well as to reduce USDA inspections at pork plants.70

At many plants, workers cannot step away from the line even to use the bathroom: there are so few official bathroom breaks that urinary tract infections are common.71 When the COVID-19 outbreak began, spreading quickly through meatpacking plants across the country, workers in at least one Missouri pork plant reported not wanting to cover their mouths while coughing because they might miss a piece of meat on the line, which can result in disciplinary action.72 (The lack of bathroom breaks for handwashing also has become a greater problem, because of the virus.)

The Environmental Toll of Hog Farms

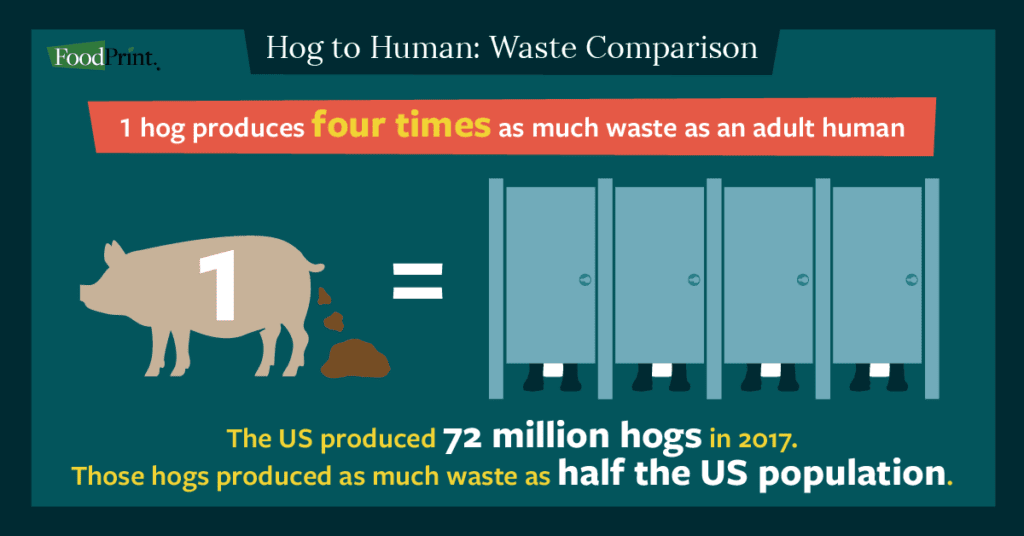

Besides pork, the largest output by far from hog CAFOs is manure. Despite the mind-boggling volume of the stuff, no state or federal agency tracks CAFO waste, so it is impossible to know the extent of the problem with much specificity. A 2020 Food and Water Watch report estimates that industrially-raised hogs produce as much waste as half the US population.73 One hog produces two to four times as much waste as an adult person. In North Carolina, the 1.9 million hogs in Duplin County, the top hog-producing county in the country, generate as much waste as the entire Boston metropolitan area, while the 1.3 million hogs in Washington County, Iowa, produce as much waste as San Diego.74

But there is a big difference: human waste is treated in municipal sewer systems and subject to strict regulations. There is no such requirement for animal waste, which is stored in pits and applied untreated as fertilizer to farm fields. Hog waste contains nitrogen and phosphorus, which are important crop fertilizers but toxic in excess; bacteria like E. coli; antibiotic residue; heavy metals; cleaning solutions; animal blood; and other chemicals.75

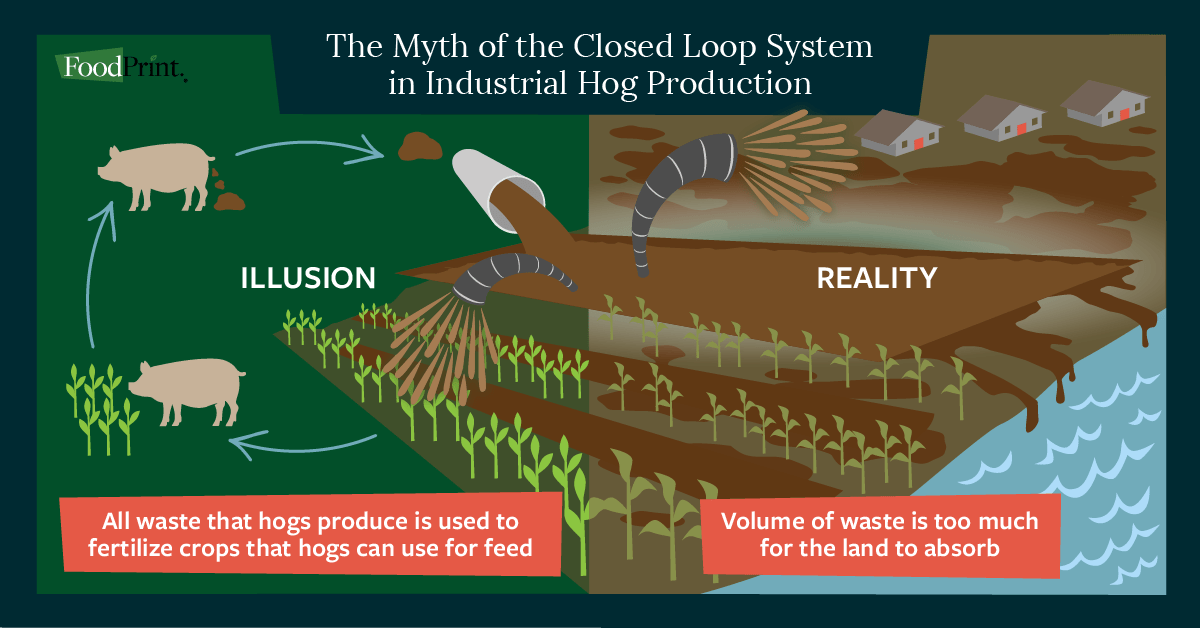

One myth perpetuated by the pork industry about raising hogs in confinement is that the system is a closed loop: hogs produce waste, the waste fertilizes crops, the hogs eat the crops. The reality is that the volume of waste vastly outstrips not only the nutrient needs of the crops, but the land’s capacity to absorb it. All the excess waste — and everything else in it — runs off the land in the rain, ending up in wells, rivers, lakes and eventually the ocean. A dead zone the size of Connecticut develops in the Gulf of Mexico annually, in large part from the runoff of animal waste along the vast Mississippi watershed. Similar water quality crises can be found in rivers throughout the country and in privately owned wells all over rural America.

Manure Management

If all this waste doesn’t go through a treatment plant, what happens to it? Two common ways of storing and disposing of it are inexpensive for the industry, but have significant costs to the surrounding community.

At hog CAFOs in the South, especially in North Carolina, waste is flushed from the barn into large ponds, called lagoons, which hold millions of gallons and can cover several acres. The mix of waste products and bacteria added to break down the sludge can make the lagoon a bright Pepto-Bismol pink. When the lagoon is full, the liquid is sprayed with a sprinkler system onto surrounding fields. While the industry touts this as fertilizer, the spray schedule is determined by the need to empty the lagoon, not the need to feed the crops. The spray system is used for easy coverage including onto growing crops, but it is imprecise, spraying liquid manure into the air, where it can be picked up by the wind. The manure falls not just on the cropland, but on neighboring houses and property, rendering the community practically unlivable. North Carolina resident and organizer Elsie Henning has lived next to a spray field since 1986. She describes manure glistening on the screens of the house after the spray, and her mother, who lived on the land for 99 years until her death, had become a “prisoner in her own home,” unable even to sit on the porch due to the flies and stench.76

In the Midwest, it is more common for CAFOs to store hog waste in a pit directly under the hog barn. The hogs, living directly over their manure, can develop lung and respiratory problems, and the barn does little to contain the smell, which permeates the region. The manure gets cleared out twice a year and spread on fields with a manure spreader or injected into the soil. The waste can be spread onto the bare ground only in this way, once crops are harvested in the fall or before they are planted in the spring. Without plants holding the soil in place, much of the waste washes right off during rainstorms or when the snow melts.

These so-called manure management systems are inadequate for containing the vast amounts of untreated waste produced by millions of hogs across the country. Many storage lagoons are unlined, and even those with clay or plastic linings are prone to leaks. In the south, hurricanes can wash out the lagoons: in 2000, the aftermath of Hurricane Floyd horrified the nation with images of hog waste and piles of dead hogs; nothing had changed by 2018 when Hurricane Florence overflowed 33 lagoons across the state.77 The impact is far-reaching on both the environment and the community.

Environmental Injustice

Even worse, in some parts of the country, these environmental disasters disproportionately impact communities of color. Mostly-white Iowa is the top hog-producing hog state, but the top two hog counties in the country are in North Carolina, in an area that had one of the highest concentrations of enslaved people in 186078 and is currently majority Black and Latinx. A 2014 study found that African-Americans and other people of color in North Carolina are 1.5 times more likely than white people to live near an industrial hog operation.79

North Carolina community organizers have been bringing attention to this injustice for decades, fighting the state-level CAFO permitting laws that allow the operations to be overwhelmingly sited in these communities. Despite the clear research and years of complaint, the North Carolina environmental agency, long in the pocket of the pork industry,80 has refused to revise its CAFO permitting laws, while organizers have been subjected to intimidation, including threats of legal action, violence and job loss.81 Organizers filed a 2014 civil rights complaint with the US Environmental Protection Agency (EPA),82 and following a 2017 investigation, the EPA expressed “deep concern” that North Carolina’s hog laws were discriminatory and ordered changes.83 However, the EPA investigation itself was hampered by the ongoing close relationship between the state and the pork industry, including when industry representatives were invited to what was supposed to be a confidential negotiation between state representatives and community organizers.84 North Carolina did revise its permitting process in 2019 and addressed some of the problems, but made none of the systemic changes that organizers had called for or that the EPA had ordered.85

Disease and Public Health

The coronavirus pandemic revealed another form of injustice, as meatpacking plants, with their workforces made up mostly of immigrants and people of color, became hotspots for the virus. As of June 2020, cases at pork packing plants accounted for 30 percent of meatpacking cases (beef and chicken accounted for 20 percent and 11 percent of cases, respectively). Across the industry, the same top three meat companies, Tyson, JBS and Smithfield, had the highest number of individual cases.86

As pressure mounted for the plants to close to slow the spread of the virus,87 pork industry executives warned of potential pork shortages,88 stoking consumer fears to build support for staying open. Executives and local government officials used racist language to blame workers themselves rather than plant conditions for the spread of the virus.89 President Trump’s order for the plants to reopen under the Defense Production Act did not mandate that they follow guidance from the Centers for Disease Control and Prevention for processing facilities,90 and while the pork companies were quick to say that employee safety was their top concern, they did not provide appropriate protections.91 As it emerged that the industry sent record-level exports to China in April,92 it appeared that the companies had placed profits above worker safety.

COVID-19 also served as a tragic proof that zoonotic diseases — infections that originate in animals before mutating and spreading through human populations — are a serious threat that can kill thousands, devastate communities and stall entire economies. While COVID-19 originated from wild animals killed for human consumption, many public health experts warn that the industrial meat production system in the US is an even more fertile breeding ground for future infections.93 Hogs are particularly concerning, given their susceptibility to influenza-type viruses that can quickly mutate and spread to human populations.94

This situation isn’t just hypothetical: The 2009 outbreak of H1N1, also known as swine flu, was ultimately traced to a hog CAFO in Mexico. Researchers studying that strain also determined that the virus causing the outbreak had been transmitted between pigs for nearly 10 years before a spontaneous mutation allowed it to infect humans, demonstrating how difficult it can be to predict and control these infections.95 After it mutated to infect humans, the 2009 strain of H1N1 killed an estimated 152,000 to 575,000 people within a year, and other strains continue to circulate.96 Meanwhile, researchers studying hog CAFOs in China have found related H1N1 strains that are common in both hogs and workers, with up to 10.4 percent of sampled workers testing positive for antibodies to the virus, indicating prior infection. While these strains haven’t yet mutated to be a serious threat to human health, the presence of DNA from avian influenza viruses in these strains is a worrying indication that they can mutate quickly and jump between different kinds of hosts.97

Influenza-type viruses cannot be passed on through pork and other food98 making workers on factory farms the first victims of zoonotic disease. Much like meatpacking became a hub for COVID-19 spread, CAFOs could transmit future infections into the community: epidemiologists modeling the spread of potential flu infections found that communities with a high proportion of CAFO workers could see up to 86% more cases of flu than others.99 The fact that CAFO workers often come from communities of color with less access to medical care mirrors the injustices of the COVID-19 outbreak.

While controlling influenza and other viral infections is in the best interest of both pork producers and the public, it isn’t appropriately prioritized. Hog farmers try to prevent infection by quarantining hogs before adding them to herds and limiting visitor access to facilities, but once diseases are present, controlling their spread is nearly impossible in the crowded conditions of a CAFO.100 While diseases can still impact smaller farms with fewer animals, they are less likely to serve as amplifiers for disease.101 Ultimately, preventing the spread of these infections relies on two factors; first, improving worker protections against disease, and second, decreasing crowding and stocking rates for hogs on farms. Sadly, because these measures would reduce profitability, zoonotic diseases from hog CAFOs continue to present a pressing public health risk.

Water Pollution

As noted, water pollution is the number one catastrophe of factory hog farms. With no national database of hog confinement operations, there is also little information on the number (or frequency) of manure spills, which can be caused by equipment failures, storage overflow, transport accidents, severe weather, or, occasionally, by deliberate actions.102 Runoff from overapplication to farmland is equally a cause of water pollution.

Hog manure contains nitrogen and phosphorus, which are important for crop growth; but in high concentrations these elements are toxic to fish and aquatic species and in drinking water. Nitrogen pollution from livestock manure increased nearly 50 percent from 1930 to 2012.103 In public water systems, the legal limit of nitrate in drinking water is 10 parts per million (ppm). Higher nitrate levels can cause blue baby syndrome, a potentially fatal condition for infants, and studies have shown increased rates of numerous cancers and birth defects at concentrations of just 5 ppm.104

In Iowa, the top hog-producing state in the nation, water regularly tests at or above those limits, with levels rising consistently since 2002. A study of almost 55,000 private Iowa wells found that they averaged 4.4 ppm of nitrate, with nearly one-quarter averaging 5 ppm and 12 percent at or above 10 ppm. Forty percent also tested positive for coliform bacteria from hog manure at least once in the 15-year testing period, and nearly 8 percent had the bacteria every time they were tested.105 In the state capital, half a million city residents drink treated water from the Raccoon River, which drains 1.7 million acres of farmland that are heavily spread with hog manure. One test period found the average nitrate level in the river was over 11 ppm. After treatment by Des Moines Water Works, average levels fell to 5.16 ppm, but individual samples ranged from 0.08 ppm to 9.21 ppm.106

Both nitrogen and phosphorus accelerate algae growth, which can in turn entirely eliminate the oxygen in a body of water, killing all life in so-called “dead zones.” The area of oceanic dead zones increased by one-third between 1995 and 2007,107 along with the rise of CAFOs.

Nationally, while data from the most recent EPA National Rivers and Streams Assessment is over 10 years old, 40 percent of the nation’s river and stream length was shown in 2008 to have elevated levels of phosphorus, and 28 percent had elevated levels of nitrogen,108 mostly from fertilizer and animal waste runoff from farmland.109 In Iowa, 2016 tests found 750 waterways, out of the 1,378 tested, to be “impaired,” due mainly to excessive pollution.110 A Chicago Tribune article about Illinois pollution found that pig waste impaired 67 miles of the state’s rivers, creeks and waterways from 2005 to 2014, killing nearly half a million fish. No other industry in the state came close to causing the same amount of damage.111

Who Pays?

Industry rarely has to pay for its pollution, or if it does, it’s the relatively small cost of doing business. It is nearly impossible to connect water pollution to one particular farm, and the full problem is caused by combined runoff and spills from many farms. The contract farming model puts the responsibility for waste management on farmers rather than on the meatpacking company they contract with, even though the company tells the farmer what kind of manure management system to build. Advocates for clean water argue that it should be the big meatpackers (often the animals’ owners), not individual family farmers, who should be responsible for cleanup of excess manure and for costs associated with installing cleaner technologies.

Air

Vast pits of hog waste, whether stored under a barn or in an open lagoon, create not just terrible fumes and odors, but toxic gases. The waste mostly breaks down anaerobically (without oxygen), which generates more than 300 volatile organic compounds. When these are inhaled, they can be absorbed so deeply in the lungs that they are exuded from the pores.112 The air inside hog houses is also full of dust, ammonia, carbon dioxide, hydrogen sulfide and other gases, giving hog workers more job-related health problems than those in any other confinement operation.113 Powerful ventilation fans blow the gasses out of the barns to make the air breathable for the hogs, blowing the contaminated air out into the community. If the fans fail, the hogs can quickly die.114 Farmers and CAFO workers have also died in horrific incidents being overcome by fumes from hog manure pits.115

The fumes and other air pollution makes life miserable for neighbors. The stench of manure drives people indoors, making exercise, play, or any other outdoor activity impossible. Elevated levels of hydrogen sulfide in the air up to three miles from a hog CAFO are associated with increased stress and anxiety; irritation of the eyes, nose and throat; respiratory symptoms; increased blood pressure; and increased child asthma.116

Property Values Plummet

With these impacts, it is no surprise that property values can drop dramatically when a CAFO moves nearby, leaving people trapped in a home they can never sell.117 A 2008 Iowa study of more than 5,000 homes found houses within three miles downwind from a confined animal farm lost as much as 44 percent of their value. Homes not directly downwind still suffered a 16 percent loss in value. And size matters: every 10 percent increase in the size of the operation meant a 0.67 percent decrease in home value.118

Antibiotic Resistance

Dust can also carry antibiotic-resistant bacteria, as can insects,119 farmers and workers,120 who can unknowingly carry the bacteria home and transmit it to family and members of their community.

Manure itself is another major carrier of bacteria.121 Animals do not digest 75 percent of the antibiotics in their systems122 and bacteria can survive in untreated manure up to a year. Manure spread or sprayed onto fields can contain antibiotic-resistant bacteria, which leech into wells, streams and rivers, endangering human health.123 Some bacteria can persist in stream sediment for weeks.124

Climate Change

While beef production has a significantly larger climate impact than pork,125 the gases emitted by hog manure lagoons contribute significantly to global warming. Hog waste produces large amounts of nitrous oxide, which has 300 times the warming potential of CO2. Hog CAFOs cause 40 percent of the total methane generated from the breakdown of all animal waste.126

40%

The percentage of total methane generated from the breakdown of all animal waste contributed by hog CAFOs

Additionally, studies show that heat-stressed pigs produce less meat, because heat slows the animals’ muscle growth and fertility, especially in animals bred for industrial production.127 As global temperatures rise, this could lead to higher pork prices, or even greater industrial hog production to make up for the losses. Greater production, of course, would contribute to further warming.

False solution: Biogas

Certain people in the hog industry and even some environmentalists suggest that the solution to CAFO waste is to turn it into energy. Anaerobic manure digesters process waste in a closed environment, using microbes, heat, water and agitation to produce several byproducts: methane that can be used for energy, liquid manure that can be used for fertilizer and solid manure that can be composted. The processed manure products are supposed to be cleansed of pollutants and be safer to use as fertilizer than untreated waste.

The USDA, state governments and the livestock industry have put significant investment into researching and developing this technology,128 and some states offer incentives for construction.129 For the industry, “waste to energy” technology lets business continue as usual, with large-scale polluting animal factories now painted as a source of renewable energy. In reality, manure digesters do not live up to their promise of cleaning waste and mitigating greenhouse gases, but instead serve as a subsidy to the CAFO industry, further entrenching the confinement model of food production.130131

Federal Laws Provide Little Oversight

How is it that these facilities are allowed to run roughshod over rural communities, polluting the air and water? The short answer is that the pork industry has a tremendous amount of political power both in Washington, DC, and in state houses across the country, and has dramatically influenced policy on large-scale farming. At the federal level, the EPA is responsible for CAFO oversight under the Clean Water Act, the Clean Air Act, and other laws. In practice, the agency’s authority has been weakened over the years by pork industry pressure.

Antitrust Laws

Big Pork has gained so much power because, as in all industries, the companies have consolidated into a near-monopoly. The last time meatpackers were so powerful, the federal government stepped in to break them up.

Back in 1906, Upton Sinclair wrote The Jungle, exposing the horrific conditions of meatpacking plants, which were then controlled by just a few powerful companies. Monopoly power like that of the meatpackers was common at the end of the 19th century; from railroads to oil, just a few firms ran the economy. But as Sinclair revealed, in the meatpacking plants, monopoly power led to abuses of workers, poor quality products, higher consumer prices and other injustices. Popular uprisings against these conditions led the federal government to pass a series of antitrust laws in the early 20th century to break up monopolies (so-called “trusts”) and restore competition to the marketplace. Consolidation of meatpacking declined, leading to more small meatpacking plants, better farmer prices and improved consumer quality.132 Other sectors saw similar benefits.

But in the 1970s, pro-big business attitudes began to take hold in Washington. The standards of antitrust enforcement changed, from protecting competition and small business to protecting consumer welfare.133 So long as a company could argue that a merger would not raise consumer prices or decrease choice, it was given a green light by government antitrust enforcement agencies. Consolidation swept across the economy from transportation to banking to retail to meatpacking, so that most industries today again look like they did a century ago. Despite the consumer welfare standard, prices have gone up134 and choices have decreased, as have worker wages and farmer prices.135 The top pork companies today are also the top beef and chicken companies, and this handful of global firms has given millions of dollars to Congress to fight any attempt to curb either their influence136 or their business practices.

Water Regulations

Water protection is a key area where the industry puts pressure on the government to ease CAFO regulations. The EPA has the authority to regulate CAFOs under the Clean Water Act (CWA), by requiring permits for operation, setting pollutant limits, regularly collecting information about the facilities, and the like, all of which it does for other polluting industries.137 Over the years, the agency has issued several rules to regulate CAFOs, including requirements in the mid-2000s that new CAFOs get a permit if they discharge or could potentially discharge waste into waterways, and a 2011 rule requiring them to submit basic information about their operations. In all instances, community groups in farm states and advocates for clean water maintained that the original rules did not go far enough.138 The National Pork Producers Council and other industry groups, on the other hand, thought the rules went too far, and opposed them vigorously.139

The permit rule was overturned as a result of a pork industry lawsuit.140 The information collection requirement, which followed from a settlement after this lawsuit, had a stranger trajectory. The EPA issued the rule to collect information about the ownership, operation, size and location of CAFOs across the country, in order to track potential pollution sites as it does with other industries. The agency estimated that the rule would have applied to about 20,000 facilities. But then, rather than finalizing the rule as is standard government agency procedure, the EPA withdrew it, claiming that it would use other sources to collect the information. When community and environmental groups obtained EPA documents on the matter through a Freedom of Information Act (FOIA) request, they confirmed that the agency was not actually able to collect information on CAFOs from other sources as it had claimed. And then, in an unusual move in response to meat and livestock industry pressure, the EPA asked the groups to return the documents it had released through the FOIA request.141

Today, there is no requirement for CAFOs to report any information about their operations to the federal government under the CWA. The EPA has instead delegated enforcement of CAFOs to the states, but does nothing to oversee the state enforcement agencies, including not maintaining the most basic information about whether states are using the same set of standards in their permitting processes.142

Air Quality Regulations

Several federal laws required farms to report discharges of toxic air pollution as well, including ammonia and hydrogen sulfide, the main air pollutants from hog CAFOs. The law applied only to very large releases and so would not impact most farms, while providing important air quality and public health information for the operations it applied to.

But here, too, the livestock industry flexed its muscles. A complicated battle played out at the EPA, in the courts and in Congress for a decade over the reporting rules, with the industry fighting hard to exempt CAFOs from any reporting requirements. A 2008 exemption from reporting was overturned by a court in early 2017,143 but just a few months later — following a meeting with industry representatives like National Pork Producers Council and National Cattlemen’s Beef Association144 — the agency issued new rules exempting farm operations from local reporting requirements. The next year, Congress passed the bipartisan Fair Agricultural Reporting Method (FARM) Act, making the exemption national.145 The Nebraska senator who introduced the FARM Act received more than $230,000 from agribusiness PACs in 2017 and 2018.146

State Level Laws: Where the Sausage is Made

While the EPA technically has the power to regulate CAFOs, as we have seen, nearly everything impacting CAFO operations happens at the state level, from whether local counties are allowed to block a proposed new operation to how close to a school a hog barn can be sited. In the top hog-producing states of Iowa and North Carolina, like other major farm states, the livestock industry has successfully lobbied for lax environmental laws as they apply to large farm operations, backed up by weak enforcement. States have passed laws limiting local communities from having a say in the siting of new or expanding CAFOs or making it nearly impossible for impacted neighbors to sue a CAFO.

Right to Farm

In top farm states, laws prohibit citizens or local governments from opposing a large hog operation or other industrial farm. Called “right to farm” laws, they were passed starting in the 1970s to protect farmers from “nuisance” lawsuits brought by people who had just moved to the country and were not used to the sounds and smells of a working farm. More recently, though, the livestock industry has weaponized right to farm laws against rural communities. The laws in many states protect industrial livestock operations from lawsuits by neighbors, even when they are the established residents and the CAFO is new.

In a recent case in Indiana, a farmer converted his land from one kind of agricultural zoning to another to build housing for 8,000 new hogs. The Indiana Right to Farm law specifically says that conversion from one kind of farm zoning to another is not a legally significant change in operation, thus allowing new buildings to be seen as part of the decades-old farm rather than as a new nuisance. The farmers’ neighbors thus had no right to sue, despite the 50 percent drop in the values of their own decades-old homes.147

Occasionally, citizens can challenge a CAFO with a nuisance suit, but state legislators — especially those taking campaign contributions from industry representatives — typically devise another law or amendment to make it even harder to sue. In 2018, North Carolina residents brought 26 federal nuisance lawsuits against Smithfield, for decades of diminished health, property values and quality of life that resulted from their hog operations. As of mid-2020, the plaintiffs had won all five of the cases that had gone to trial. But in the meantime, the North Carolina legislature passed a law severely limiting who has grounds to bring a nuisance suit, which will effectively stop future suits from ever getting to court.148 Another new law limited the maximum damages for such a case. That one was deemed retroactive, so although the juries awarded the plaintiffs nearly $550 million in the five cases, under the new law, the court lowered the damages to $98 million.149 The architect of the changes, NC State Representative Jimmy Dixon, collected $115,000 in campaign contributions from the pork industry before introducing the legislation.150

Local Control

Many states with stricter rules for CAFO siting allow counties or townships to have a say in specific siting decisions, known as “local control.” Communities best know their own needs, including whether their land, water, health, social services and economy can absorb a new or expanding animal feeding operation. In states with local control over CAFO siting, the county planning, zoning or health board can pass an ordinance spelling out the rules that a CAFO must follow to be approved for siting in the county. Some local governments use the ordinance to prohibit CAFOs altogether.

While local control applies to all kinds of CAFOs, the pork industry has done the most damage in pioneering aggressive efforts to eliminate it, so that the growth of hog operations could go unchecked. In North Carolina, counties lost local control in 1991, in a bill sponsored by “Boss Hog” Assembly Member Wendell Murphy, who was also the nation’s largest hog producer at the time.151152 In Iowa, a sweeping state-level, pro-CAFO bill changed the farming landscape in 1995 and gutted local control. While in Missouri, rural advocates fought legislative attacks on local control for nearly a decade before a bill was passed in 2019 eliminating it, despite fierce opposition from citizens across the state.153 Local control supporters are suing to overturn the new law.154

Environmental Laws

Right to farm laws and local control broadly impact how much say a community has over a new or expanding CAFO. It is the state environmental laws and regulations — the Clean Water Act authority, which the EPA delegates to states — that determine how the CAFO will look, where it can be sited and who needs to be told about it. These laws can limit CAFO development in many ways that can cause more or less pollution, including requiring a certain setback from schools, homes and waterways, strict laws on waste discharge, or strong regulation of gas or dust emissions.155 Some states require all confinement animal operations to have a permit in order to build or operate, which allows the state to monitor and inspect the facilities.

The environmental laws are where the rubber meets the road in terms of CAFO development. States looking to attract new animal operations are likely to quietly change these laws to be friendlier to CAFOs. While these measures are publicly available, they are usually tucked into little-read state water or air statutes and are in practice familiar chiefly to those with a direct interest — like the pork industry. Lawmakers are more likely to hear from representatives of meatpacking plants or trade groups (seeking to weaken these provisions) than from citizen groups wanting to make them stronger. In Iowa, community members frustrated with their state’s lax CAFO regulations and lack of enforcement appealed to the EPA in 2007, arguing that EPA has delegated enforcement to the state, but the state is failing at those responsibilities.156 Although EPA’s initial finding in the investigation agreed with the complaint, a five-year workplan between the EPA and the state did not result in any major changes to the state’s operations.157 Iowa citizens and community groups are now petitioning the state legislature instead for a moratorium on new CAFOs in the state. 158

Tax Exemptions

Finally, the tax structure of many states favors large livestock operations, with many exemptions for items such as livestock feed and medications.159160161162 Some of these exemptions are advantageous for small farms as well, but they benefit large operations much more: the benefit of a tax exemption for feed for 2000 confined hogs is significantly greater than for 20 animals that primarily forage and eat only supplemental feed.

Most significantly, many states have tax exemptions for building animal confinement barns and manure pits. CAFOs put an environmental and economic burden on rural communities, through heavy use of roads and water, and cleanup of manure spills. Tax exemptions keep them from paying their fair share to support the government services they use. One study of these exemptions for hog facilities estimated that $70 million to $165 million worth of CAFO property was exempt,163 robbing the state of much-needed funds, including those needed to address CAFO pollution and clean-up.

Consolidated Industry Power

The pork industry reacted to the coronavirus pandemic by denying virus outbreaks at its processing plants, postponing temporary closures for as long as possible, blaming workers for virus spread, stoking fears of a food shortage, lobbying the government to reopen the plants — all the while shipping record-high exports to China. To many longtime industry watchers, including meatpacking workers and communities that have fought new CAFOs, this is just business as usual164 for an industry that has grown so powerful that it is accustomed not only to getting its way, but to creating the narrative for what people think is possible.165

Who Makes the Laws?

At nearly every turn, the pork industry has had tremendous influence on lawmaking, beginning in the late 1980s, when raising hogs in confinement was still new and North Carolina legislator and hog magnate Wendell Murphy passed new state laws supporting growth of the nascent industry.166 Similar laws in Iowa and other states followed, along with industry attacks on any efforts at environmental regulations, as we have seen. The major pork companies and their trade groups also successfully fought a country of origin labeling measure167 and basic contract fairness protections for farmers,168 both very popular with farmers and consumers,169 and worked for increased line speeds at meatpacking plants,170 deregulation of meat inspection171 and export-focused trade deals,172 all measures that passed despite little popular support.

As these laws and regulations made individual pork companies successful, they vertically integrated and merged eventually into the few companies that control the industry today. Their growing size gave them more political power, through direct lobbying and other avenues. For instance, as public funding for agricultural research universities has declined in recent decades, private funding from the agriculture industry has filled the gap. This funding not only determines what research gets funded or not (e.g., research on breeds that do well in confinement rather than expanding knowledge on pasture-based systems), but it can make the institution and its researchers fearful of engaging in inquiries that could reflect negatively on the industry. In one example, Jim Merchant, a former dean of Iowa University’s School of Public Health, was barred from completing research on hog farm emissions as an emeritus professor, even though the research had been permitted in the past. He put it bluntly: “The administrators and the faculty at these land-grant universities are heavily influenced, if not beholden, to agricultural interests.”173

Checkoff: A Farmer Tax to Promote Industry Interests

Besides the direct political power that the largest pork companies have, they have other entities speaking on their behalf. Farmers pay a mandatory fee, called a checkoff, every time a hog is sold. The funds go to a commodity trade group, the National Pork Board (NPB), for research (including at universities as previously noted), education, and promotion, with the goal of increasing pork consumption in the US and abroad.174 NPB’s most famous slogan, “Pork. The other white meat,” is still recognizable even though it was retired a decade ago.

- Checkoff

- A mandatory fee paid by farmers to a commodity trade group, the. National Pork Board (NPB) every time a hog is sold.

Legally, checkoff monies are not allowed to be spent on political lobbying, but a partner organization, the National Pork Producers Council (NPPC), works with NPB to advance the pork industry’s political agenda. The two groups are closely linked, enjoying cozy financial relationships.175 NPPC’s lobbying agenda has long represented the interests of the big meatpackers, fighting against: a leveling of the playing field for small farmers, the expansion of environmental regulations, labeling transparency and increased competition within the livestock industry.176

In the early 2000s, when the independent hog market was still robust, the hog farmers who actually pay the checkoff fee cried foul, frustrated at having their own money be used against them to promote a market in which they were losing money due to consolidation.177 In a national vote, pork producers voted to end the mandatory checkoff fee.178 President Bill Clinton’s USDA began to dismantle the program, but the decision was reversed by the incoming George W. Bush administration, and both NPC and NPPC have continued to drive pork promotion and policy ever since.

Too Much Pork

In April 2020, as Smithfield dragged its feet in closing the Sioux Falls plant, despite hundreds of employees testing positive for COVID-19, the company’s CEO, Kenneth Sullivan, issued a statement saying, “It is impossible to keep our grocery stores stocked if our plants are not running.… We have a stark choice as a nation: we are either going to produce food or not, even in the face of COVID-19.”179 While industry giants and their allied trade groups have built a narrative that pork shortages could result from potential supply-chain interruptions, this is an unlikely reality.

25%

The amount of pork produced above what the US demand requires

The industry produces 25 percent more pork than US demand requires.180 Three new, large-scale packing plants have opened since 2017,181 contributing to a 12 percent increase in pork processing from 2017 to 2019.182 Companies have increased the number of hogs they buy from or contract to growers to meet the new capacity.

The focus on increasing production is not intended for the US, where pork consumption grew just 8 percent from 2010 to 2017. Exports, on the other hand, grew by one-third in that period.183 The industry has its eye firmly on China, where the African swine flu has decimated hog populations. Chinese demand for pork is so great that even with tariffs levied on imports from the US, the Chinese hog shortage bumped pork prices to four to six times higher than US prices. Smithfield retooled some of its packing plants in 2019 to produce pork for export to China.184 The 25 percent of pork that is typically exported grew to 32 percent from January to April 2020. In April, Smithfield and Tyson both sent near-record shipments of pork to China. In total, 129,000 tons was exported to China in April, three times more than the prior April, setting a new high.185

Communities Fight Back

As Big Pork (and the meat industry as a whole) writes the script for state and federal legislatures, regulatory agencies and research institutions, it creates a cultural narrative of inevitability186: CAFOs are the only way to raise animals; vertically integrated companies are the only way to produce meat; industrial agriculture is the only way to feed the world. The industry paints proponents of alternatives as backward and unrealistic, as though a system which offloads its environmental and public health costs onto others is not in and of itself backward and unrealistic. But this system is not inevitable; rather, it is the careful construction of the pork industry and its allies, which, through their power, mean to erase other possibilities.

But around the country, communities have been resisting that narrative of inevitability, fighting back with people power by organizing and building alternatives. In the 2019 film, Right to Harm, about the dangerous overreach of right to farm laws, agricultural economist John Ikerd says, “I see the future leadership of our rural communities rising up from the people standing up and resisting the CAFOs.”187

While Big Meat, and the pork industry in particular, has bent state and federal law to its will — running roughshod over farmers and workers, the environment, animal welfare and human health — communities have been resisting. Possibly hundreds of grassroots groups around the country are standing up to new and existing CAFOs and meatpacking plants, fighting for changes in the law to protect their communities and to expose the corrupt power of the industry. Many of these groups come together when they learn that a new operation is planned for their community; involvement with a CAFO fight often spurs local residents to get involved in local politics and to stay involved long after that battle is over.188 Other groups have been fighting for the economic, environmental and physical health of their communities for decades, with CAFOs being one of the many issues that demonstrate the imbalance of power between corporations and citizens. Some of these organizations include:

Iowa Citizens for Community Improvement (ICCI) started in Iowa’s cities in the 1970s, but began organizing with rural farmers during the 1980s farm crisis, helping to fight foreclosures and advocating for changes in federal law to keep farmers on the land. In the early 1990s, the hog industry moved into the state with a sweeping new law that removed all local control over CAFOs, exempted confinement operations from many environmental regulations and more. ICCI has worked with communities since then to fight new CAFOs around the state, with lawsuits and legislation, and by building opposition, in both urban and rural areas, to corporate farming.

The Missouri Rural Crisis Center (MRCC) was founded by farmers during the 1980s farm crisis, fighting farm foreclosures and providing support and emergency aid to neighbors in need. After the passage of Iowa’s hog bill, MRCC spent years fighting off similar industry tactics in Missouri, including attacks on local control and expansion of right to farm laws. Meanwhile, the consolidation of the pork industry was forcing thousands of small-scale Missouri hog farmers out of business. MRCC helped some of those farmers start Patchwork Family Farms, a pasture-raised pork cooperative that provides an alternative market for independent family hog farmers. Today, Patchwork has about 30 farm members and its pork can be found across mid-Missouri, while MRCC continues to organize with rural communities for their needs and against excess corporate power.

In North Carolina, African-American residents living with the catastrophic impact of hog farms on their air, water and health have been organizing since the late 1990s as the North Carolina Environmental Justice Network (NCEJN). Hog confinements are not the only dirty industry disproportionately located in communities of color in North Carolina (and around the country); there are also poultry CAFOs, industrial waste sites, fracking and landfills. The Network brings together 30 grassroots organizations, mostly led by people of color, who are fighting these racist siting policies in their backyards, through community education and organizing, citizen science and political action. The 26 lawsuits against Smithfield noted above were brought by NCEJN members.

These three groups, which are profiled at length in an accompanying publication, explicitly fight the power of the pork industry with the power of people. For instance, the lawsuits NCEJN members filed to address the pollution they live with were specifically targeted at Smithfield, not at the contract farmers growing their hogs, who NCEJN members see as stuck in the same corporate-controlled system that is poisoning their air. MRCC says, “We need local control, not corporate control,” framing all of their issues as preserving democracy in the face of a corporate takeover. As Iowa CCI puts it, “Everyday people can be a powerful force for justice.” Other groups around the country are doing similar work — find some of them at righttoharm.film/ and support their work if you can.

Supporting Small Farmers and Pastured Pork

With so much money and power concentrated in the pork industry, how does a bacon lover support a better system? It can be challenging to find alternatives, but they do exist. All around the country, farmers are overcoming many challenges to raise pork in a more natural way. They need support from consumers eager to buy their product, and given that the power of the global meat industry is stacked against them, they also need support from citizens eager to get involved in community groups and take political action for a different kind of food system.

Pastured Pork

While the term “pastured pork” does not have a strict definition, it is generally understood to mean coming from hogs raised outdoors in a forest or field, with enough space to move around, express their natural digging and rooting behaviors, and eating a varied diet. Hogs can be an important part of a diversified farming system, as they eat weeds, pests and farm waste and their manure helps to build healthy soil. Pigs are smart and curious; being outdoors allows them to maintain their social groups and keeps them healthy and entertained189

Hogs raised in confinement are bred for fast growth and lean muscle. They tend to be jumpy and aggressive. Farmers raising pastured pork can instead select from a wide range of other breeds, including “heritage” breeds and others. In comparison to confinement breeds, hogs that thrive in the outdoors are heartier and calmer by temperament and have higher levels of fat, leading to a marbled meat richer in flavor.

Deep Bedded Systems

As another alternative, some larger operations have transitioned to deep bedded systems. These are large barns with a floor of deep straw or similar material, which allows the hogs to spend time in social groups and express other natural behaviors.190 Sows are provided secluded areas for birthing and nursing piglets rather than being put into metal crates. In this kind of environment, as on pasture, pigs establish certain areas for eating and resting and other areas for waste. The bedding absorbs the waste, keeping it contained and low-odor. By the time it is removed, the manure and bedding has partially or fully composted, making it much safer to spread as fertilizer.191

These systems are much less expensive to build than a confinement barn192 and they can house more animals than a pasture system. For the consumer looking to eat pork produced humanely and with environmental sensitivity, Brands like Niman Ranch sell pork from hogs raised in these systems; deep bedded barns with sufficient outdoor access are included in standards like Animal Welfare Approved.193

Challenges for Small Pork Producers

But as we have seen, despite the explosion in demand over the last decade for pork raised in better ways, the market is still small; auctions where farmers could sell their herd to the highest bidder no longer exist, small-scale processing facilities are few and far between and consumers balk at paying the true cost of production for well-raised meat. It is a challenging market. Small operations near towns and cities can sell directly at a farmers market or as part of a community-supported agriculture program, and slightly larger farms can sell to restaurants; either way, farmers have to do a lot of work to find a buyer — essentially becoming marketers as well as producers of their products.

Bringing in the Middleman

In some areas, cooperatives like MRCC’s Patchwork Family Farms, regional middlemen like Firsthand Foods in North Carolina, or branded programs like Niman Ranch take care of the marketing and sales side, buffering risk for the farmers. These efforts source product from multiple farmers, making it easier to work with a restaurant or store that needs a reliable supply of pork. While one farmer may have trouble working with one restaurant that wants to buy only pork chops and bacon (one pig yields a limited amount of each along with less popular cuts), an aggregator can on the other hand supply enough of those higher value cuts while working with processors and buyers to find a market for the rest of the animal.

Consumer Choices: Finding Pork You Can Trust

Your best bet for finding pork raised by independent farmers outside of the corporate system is to buy direct, from a farmers market, community-supported agriculture or similar. Research whether your region has a cooperative of pork producers or a local pastured pork brand that sells at restaurants and local stores.

The bad news is that the popularity of locally-raised meat means that fraud has become more common.194 If a restaurant menu promises “pastured” pork that seems surprisingly inexpensive, ask questions, like which farm it’s from. Follow up with the farm to confirm that they actually sell to that restaurant.195

Raising hogs on pasture is labor intensive and expensive, from the individualized care to labor-intensive pasture management to costly processing. Pasture-raised pork can be many times more expensive than industrial-raised pork. Maybe that means you buy it less often and eat it in smaller portions or as an accent or flavoring to your meal. Each time you buy direct from a farmer is an investment in a different kind of food system, controlled by people and communities rather than big business.

Labels

Labels can be complicated. There are labels that tell you about animal welfare and the environment, but they can be hard to find. And if you’re looking for pork produced by an independent farmer rather than by highly consolidated Big Pork, there is no label for that. That said, a combination of labels might be your best bet: for instance, a sausage labeled Animal Welfare Approved and USDA Organic would be better than either one of those labels on their own.

Where available, look for these labels:

- Animal Welfare Approved

- Global Animal Partnership Step 5+

- USDA Organic (good for organic feed and no antibiotics or other drugs, but little guarantee of the conditions in which the hogs were raised, if they had outdoor access, or other welfare concerns)

Conclusion

Over the last 30 years, the pork industry has transformed farming and the food system, making cheap pork ubiquitous, passing on its costs, and raking in the profits. Its strategy has caused untold damage to rural communities, worker health, land and waterways, animal welfare and beyond. The ongoing spread of the coronavirus in meatpacking plants is only the latest, deadly example.

The good news is that across the country, people are building citizen power to fight corporate power and reclaim their communities. Against all odds, farmers are finding ways to raise pigs on the land and get them to the growing number of people who want sustainably-raised pork by producers making their own decisions and getting a fair price.

As consumers and as citizens, at the supermarket and through civic action, we must organize against Big Pork and all its tactics and invest in building a healthier, safer and more delicious future.

Top photo by timestudia/ Adobe Stock

Researched and written by:

Hide References

- Corkery, Michael, and David Yaffe-Bellany. “The Food Chain’s Weakest Link: Slaughterhouses.” The New York Times, The New York Times, 18 Apr. 2020, www.nytimes.com/2020/04/18/business/coronavirus-meat-slaughterhouses.html.

- Smithfield Foods. “Smithfield Foods To Close Sioux Falls, SD Plant Indefinitely Amid COVID-19.” Smithfieldfoods.com, Smithfield Foods, 12 Apr. 2020, www.smithfieldfoods.com/press-room/company-news/smithfield-foods-to-close-sioux-falls-sd-plant-indefinitely-amid-covid-19.

- Schlosser, Eric. “America’s Slaughterhouses Aren’t Just Killing Animals.” The Atlantic, Atlantic Media Company, 14 May 2020, www.theatlantic.com/ideas/archive/2020/05/essentials-meatpeacking-coronavirus/611437/.

- Douglas, Leah. “Mapping Covid-19 Outbreaks in the Food System.” Food and Environment Reporting Network, The Food and Environment Reporting Network, 22 Apr. 2020, thefern.org/2020/04/mapping-covid-19-in-meat-and-food-processing-plants/.

- Douglas, Leah, and Tim Marema. “Rural Counties with Covid-19 Cases from Meatpacking Have Infection Rates 5 Times Higher.” Daily Yonder, 28 May 2020, dailyyonder.com/rural-counties-with-covid-19-cases-from-meatpacking-have-infection-rates-5-times-higher/2020/05/28/.

- Corkery, Michael, and David Yaffe-Bellany. “As Meat Plants Stayed Open to Feed Americans, Exports to China Surged.” The New York Times, The New York Times, 16 June 2020, www.nytimes.com/2020/06/16/business/meat-industry-china-pork.html.

- United States Department of Agriculture, National Agricultural Statistics Service. Livestock Slaughter 2019 Summary, Apr. 2020. downloads.usda.library.cornell.edu/usda-esmis/files/r207tp32d/34850245n/5712mr72x/lsan0420.pdf.

- United States Department of Agriculture, Agricultural Marketing Service. Packers and Stockyards Division Annual Report 2018, Aug. 2019. www.ams.usda.gov/sites/default/files/media/PSDAnnualReport2018.pdf.

- Shahbandeh, M. Global Meat Industry Value, 2018 & 2023. 30 Sept. 2019, www.statista.com/statistics/502286/global-meat-and-seafood-market-value/.

- MacDonald, J, and McBride, G. The Transformation of U.S. Livestock Agriculture Scale, Efficiency, and Risks, United States Department of Agriculture, Jan. 2009. www.ers.usda.gov/webdocs/publications/44292/10992_eib43.pdf?v=0.

- Lawrence, John D, and Glenn Grimes. Production and Marketing Characteristics of U.S. Pork, 2000. Aug. 2001, www2.econ.iastate.edu/faculty/lawrence/Acrobat/Staffppr343FNL.pdf.

- United States Department of Agriculture, Agricultural Marketing Service. Packers and Stockyards Division Annual Report 2018, Aug. 2019. www.ams.usda.gov/sites/default/files/media/PSDAnnualReport2018.pdf.